CSR

An outline of

DYNAX's

CSR activities

Environmental Conservation

In order to preserve the global environment, we have actively been striving to save energy, reduce CO2 emissions, reduce wastes and reuse resources.

Introduction of solar power generation

Tomakomai Plant introduces solar power generation and is working on utilization of renewable energy.

At the haed office, we have installed a carport with the solar panel, which can be used not only for our company-owned EV but also by visitors'.

We have installed a solar power generation facility in our on-site childcare facility and have realized a virtually zero CO2 emissions facility.

We have introduced carport-type solar power generation systems at Chitose and Tomakomai plants, and are working to utilize renewable energy.

Chitose Plant

Tomakomai Plant

We have introduced solar power generation at Chitose plant and are working to utilize renewable energy.

We have introduced a biomass boiler that uses wood chips to reduce gas consumption.

Replacement with LED lighting

We are proactively pursuing to replace current lighting system with low-power-consumption and low-CO2-emission LED lighting for both factory and office.

Utilization of exhaust heat from production processes

Introducing an exhaust gas boiler, we reuse waste heat generated during impregnation processes for heating and production lines to reduce gas consumption

※ An impregnation process is the process of immersing friction material base paper in resin and baking it.

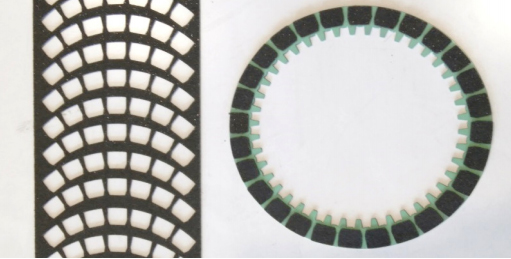

Improvement of friction material yield

The friction material used in a clutch disk, one of our main products, used

to mainly be punched out in a ring shape from raw sheets, but now it is

increasingly punched out into small pieces (dots) and assembled on to a

disk per its specification.

By adopting this method, material yield has been dramatically improved,

contributing to the reduction of waste. In addition, with these products, we

can respond to customers' various detailed demands for performance

and characteristics, and, in turn, are also helping to improve the fuel

economy of our customers' vehicles.

For conventional ring shape, material yield is improved by punching multi

rings with different diameters at the same time in nesting.

-

Environment Policy

Environmental Vision

Basic Policy -

Environmental Management

Management System

Management Committee

Internal web site

Certification of ISO14001 -

Environmental Conservation

Gas cogeneration system

Solar power generation

Replacement with LED lighting

Utilization of exhaust heat -

Contribution to Environment by Product Development

Product Development

for Low CO2 Emission

Our environmental technology

and development history -

Environmental Performance Data

Water Quality

PRTR Target Substance -

Coexistence with society

Cleaning activities

around the plant

Dynax Children's Club Flowerbed